Why AI in Vehicle Health Monitoring?

Modern vehicles generate an enormous amount of data every second. Most of them are repetitive or not very informative but hidden within are subtle signals that can indicate the early stages of a m-echanical problem. The challenge is that these signals are often buried under noise, appear inconsistently, and may depend on how the vehicle is being driven (frequency, order, and duration of readings).

This is where artificial intelligence makes a real difference. AI allows us to separate the “weak signals” that matter from the noise, by learning from patterns in vast datasets collected across different vehicle types, manufacturers, mission profiles, and load conditions.

A Simple Example: Coolant Temperature

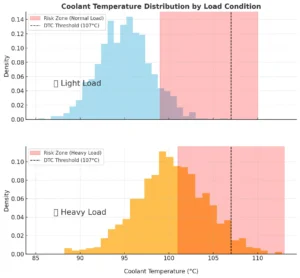

Take coolant temperature, a common J1939 parameter. Under most conditions, coolant temperatures remain below ~102°C (depending on engine type). If the temperature exceeds this threshold (e.g., 110°C), a diagnostic trouble code (DTC) is triggered, which often requires immediate inspection or even stopping the vehicle.

But what happens when coolant temperature doesn’t exceed the DTC threshold, yet hovers unusually close to it for extended periods, even when the vehicle isn’t under heavy load? This can be an early sign of a developing coolant system issue. Left unchecked, it could lead to significant downtime and costly repairs.

AI helps by recognizing these subtle patterns. Our models can distinguish between normal high temperatures during heavy load operations versus abnormal high temperatures under light load operations, flagging only the cases that truly matter.

From Raw Data to Actionable Health Scores

At Questar, our AI models have been trained by thousands of hours of real-world fleet data. They don’t just look at single points but consider frequency, consistency, and context. By filtering out extreme but normal cases (e.g., steep uphill hauling), our system pinpoints evolving concerns and translating them into a health score for each vehicle.

This empowers fleet managers to:

- Prioritize maintenance visits before a breakdown occurs

- Allocate missions based on expected load and vehicle health

- Coordinate with workshops more efficiently, reducing downtime

Visualizing the Difference: Normal vs Heavy Load

Below is an example showing coolant temperature distributions for vehicles under normal load and heavy load. Notice how heavy load operations naturally shift the distribution upward, but it’s the prolonged “red zone” cases near the DTC threshold that matter most for predictive maintenance.

Closing Thoughts

AI in vehicle health monitoring isn’t just about technology hype. At Questar Technologies, we deploy AI models that truly learn from data, identify early signs of mechanical issues, and help fleets stay on the road longer with fewer disruptions.